- Home /

- Projects /

- Dream Works /

- WallSlotRobot

WALLSLOTROBOT

Automated wall slot excavation

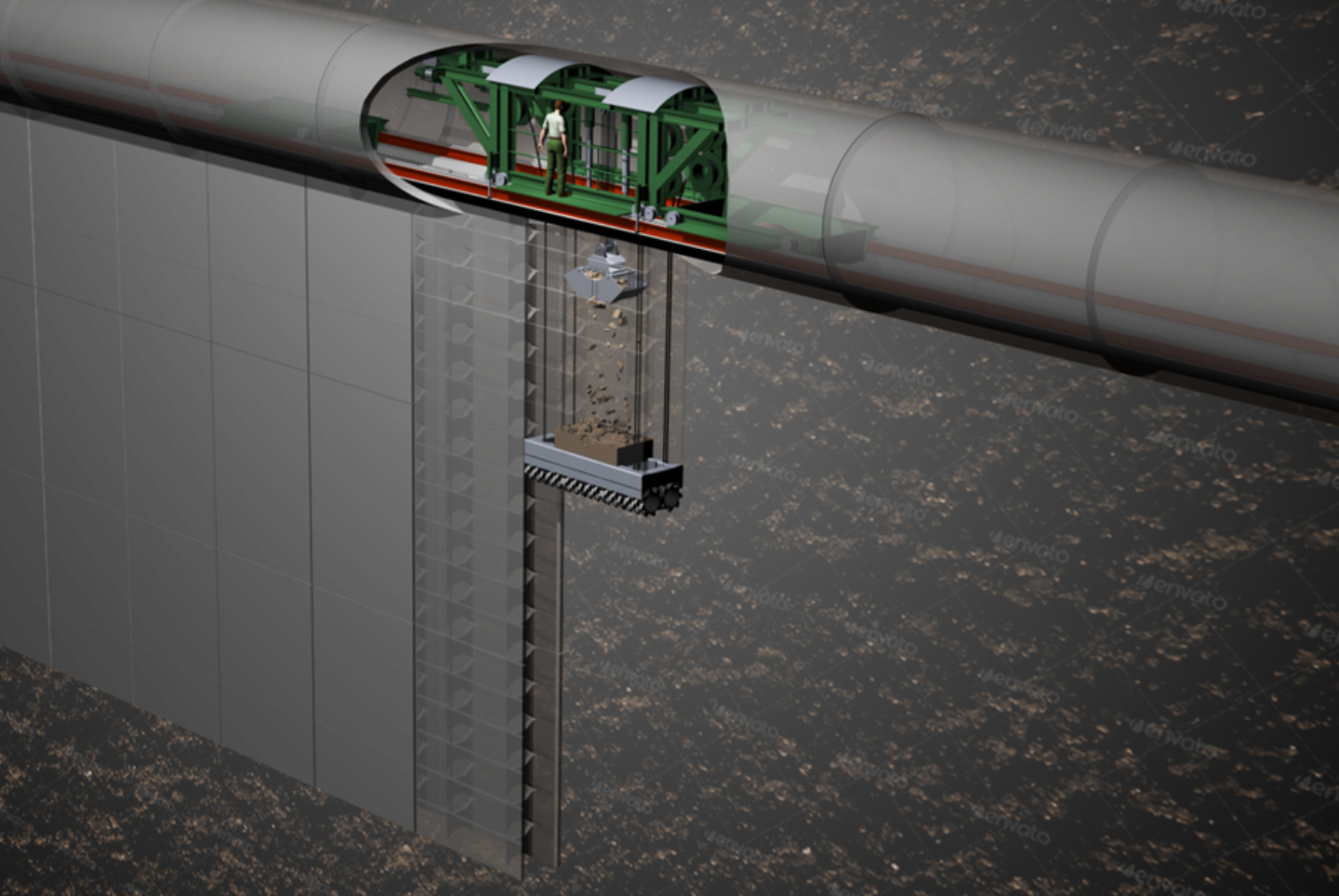

Why do we still send men 20 or 30 metres down in tiny shafts to excavate deep vertical trenches? Wouldn't it be better to let a machine do the work down there? Well, Denys has developed such a machine. It's called the WallSlotRobot, an automated trench digger, and it is fast, clean, safe and versatile.

It is difficult to excavate vertical trenches in town centres and densely built-up areas. Conventional techniques such as slurry walls are impossible due to the limited manoeuvring space, so it is still common practice in some countries to have excavations carried out by workers going down the shafts in tiny spaces of about 1 by 3 metres. It's a rather intimidating job.

That's why Denys has developed the WallSlotRobot, a technique that lets a machine do the dirty work:

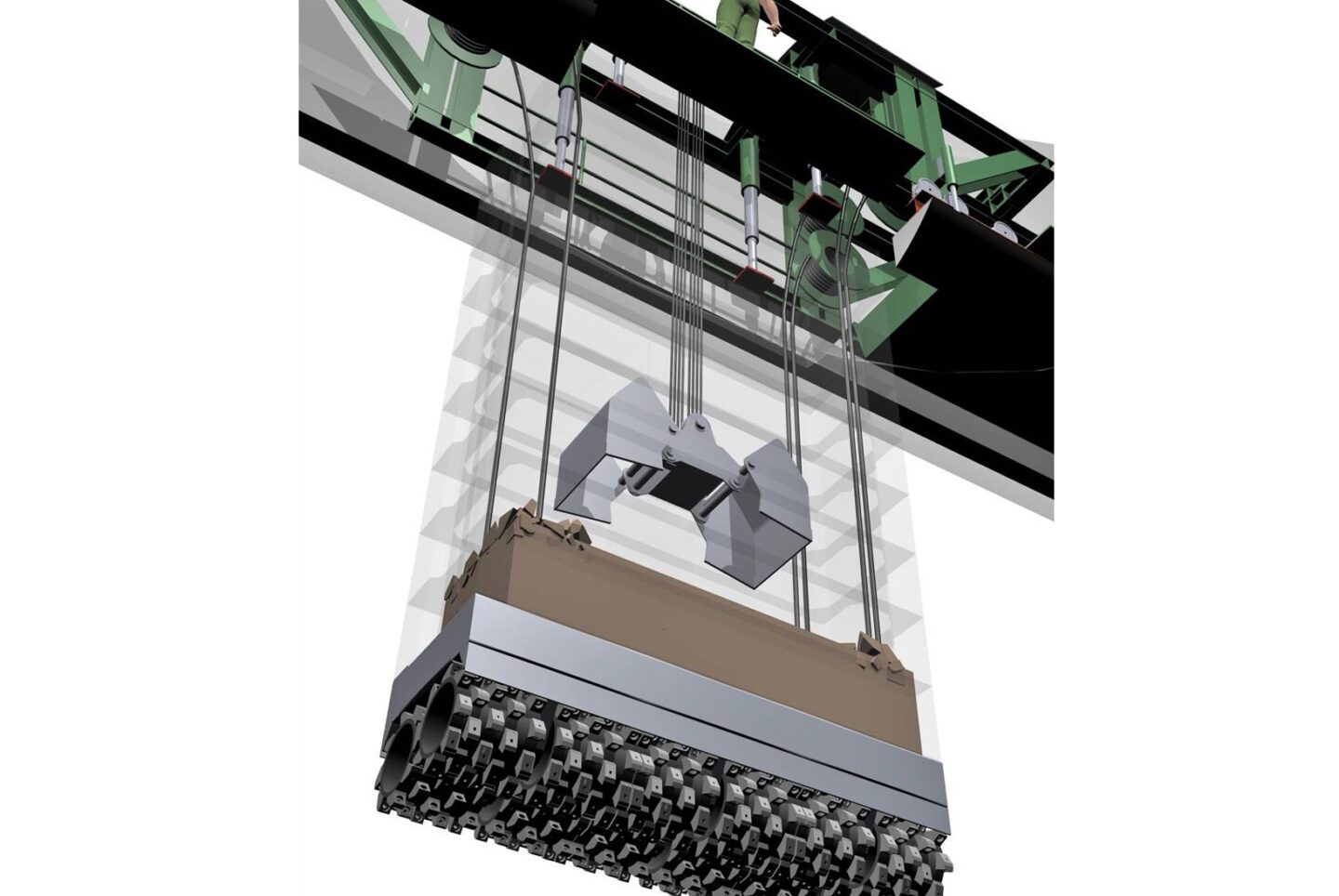

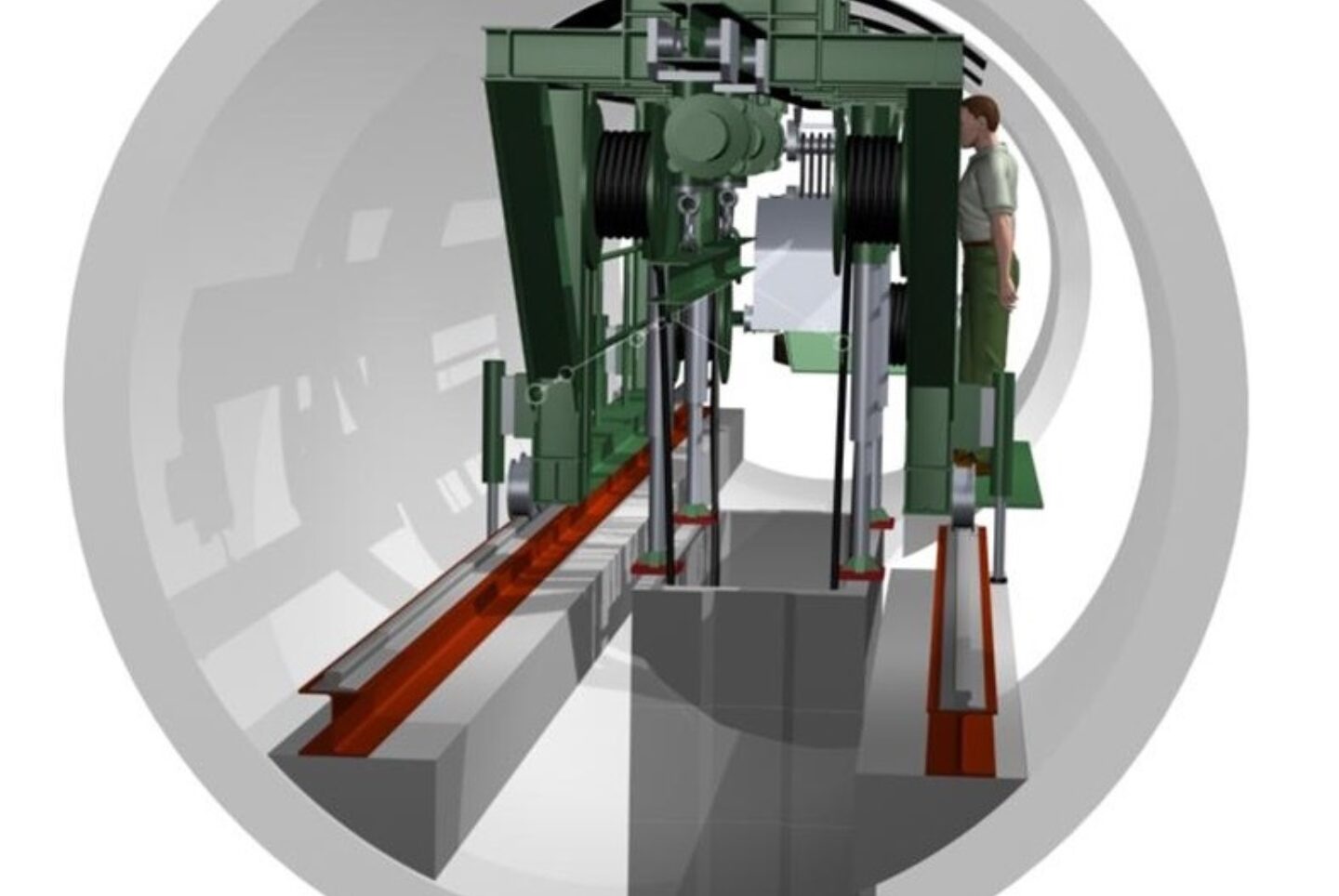

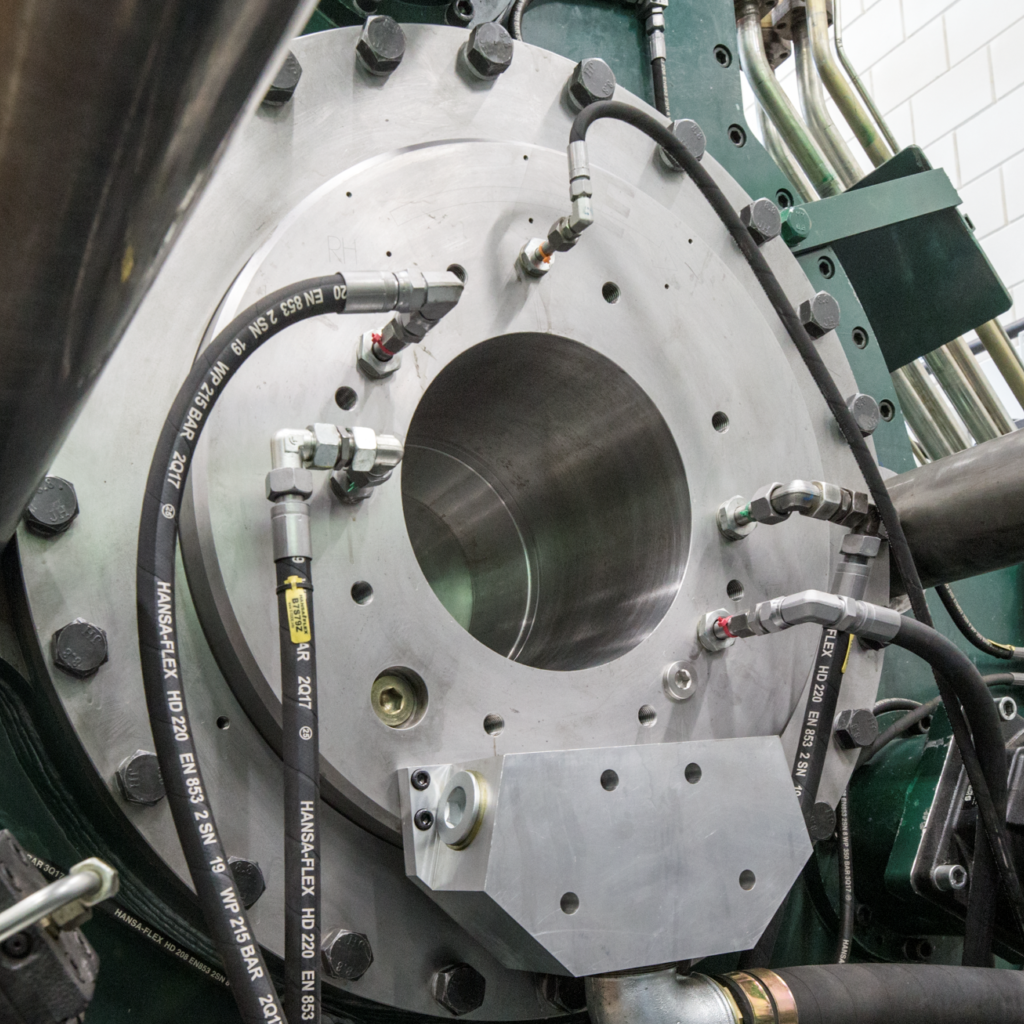

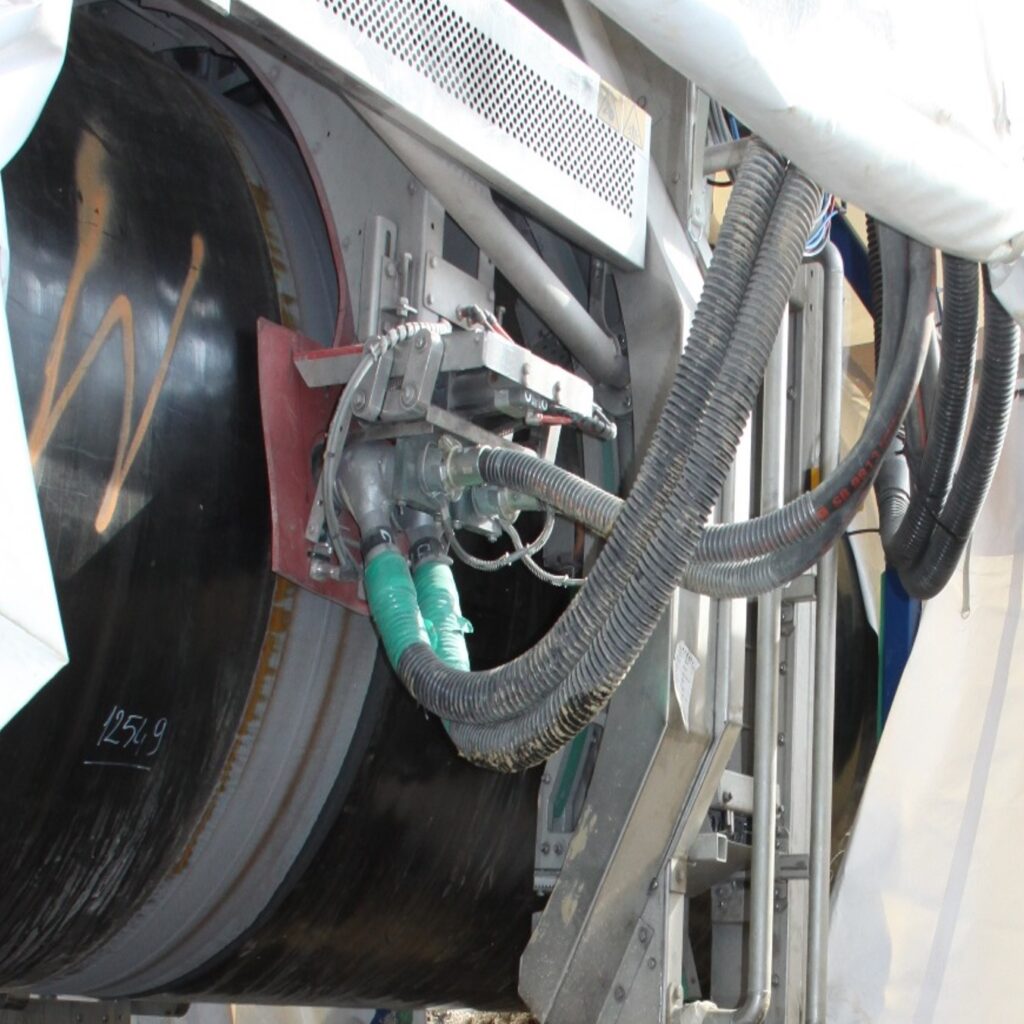

- Reinforced concrete elements are driven into the soil by means of four hydraulic cylinders to form a shaft.

- An excavator machine, attached to the first concrete element, digs into the soil. The soil is taken up and removed via a rail on ground level.

- Once the shaft is finished, the excavator is removed.

- Reinforcement is lowered into the shaft and concrete is cast in place.

The system has many advantages, besides the obvious one of working in comfort and safety. While manual excavation usually requires a week to complete, this technique takes just two days, one for the excavation and one to cast the concrete. The technique also enables the consecutive excavation of neighbouring shafts. And, unlike with slurry walls, the concrete casing makes for a clean wall surface.

The technique can be used for various types of projects such as the construction of underground railway stations, the restoration of foundations, and the extension of buildings with subterranean floor levels or underground parking space.

ANDERE PROJECTEN